Tudta volna, hogy a nagy gyárak mindig tudják, hogy mennyi folyadék van a tankjaikban? Ezt a gyárak egy speciális eszköz segítségével tehetik meg, amit ultrahangos folyadék-szint-érzékelőknek neveznek. De mitől vannak ezek olyan kiválóak? Mert tudják meghatározni, hogy egy adott tankban milyen fajta folyadék van benne, anélkül, hogy valójában érintenék azt, és hanghullámokat használnak ehhez!

Nos, milyen technológiát látasz ezekben az ultrahangos folyadék szintérzésekben? Láthatod, a folyadék-érzékelők nem érik a folyadékot, hanem egyedi hang hullámokat küldenek ki. Ezek a hang hullámok az légumban terjednek tovább, amíg el nem érik egy folyadék felületét. Ha ezek a hang hullámok visszapattannak a folyadék tetején, visszatérnek az érzékelőhöz. Az érzékelő megméri, mennyi ideig vesz igazolniuk a visszatérését, és így kapod meg a megtett távolságot. Az érzékelő tudja, hogy milyen magasra van a tankban a folyadék, ha tudja, hogy ennyi idő telik el. Olyan volt, mintha dobálós játékot játsznél, csak hang hullámokat dobtál volna át helyett egy labdát.

Hangüvegességi folyadék szint érzékelő - Nagyon pontos és meg tudja érezni a víz tartalmát. A tárolókban lévő folyadék mennyiségét egy remekességgel határozzák meg, amely 0,25%-os pontosságtól felfelé terjed. Ez azt jelenti, hogy az érzékelő még akkor is felismeri, ha csak 100 gallon folyadék van a tárolóban, és ezt csupán negyedgallon pontossággal! Nem rossz, ugye?

De nem ez mind! Ezek az érzékelők rendkívül megbízhatóak is. Nem mozdulnak, ami döntő. Mivel nem érintik a folyadékot, békén vásárolhatja őket, anélkül, hogy aggódna a kihasználtság vagy törés miatt. Ezeknek a gyárnak a megfelelő eszközök megbízhatósága kulcsfontosságú előnnyel bír.

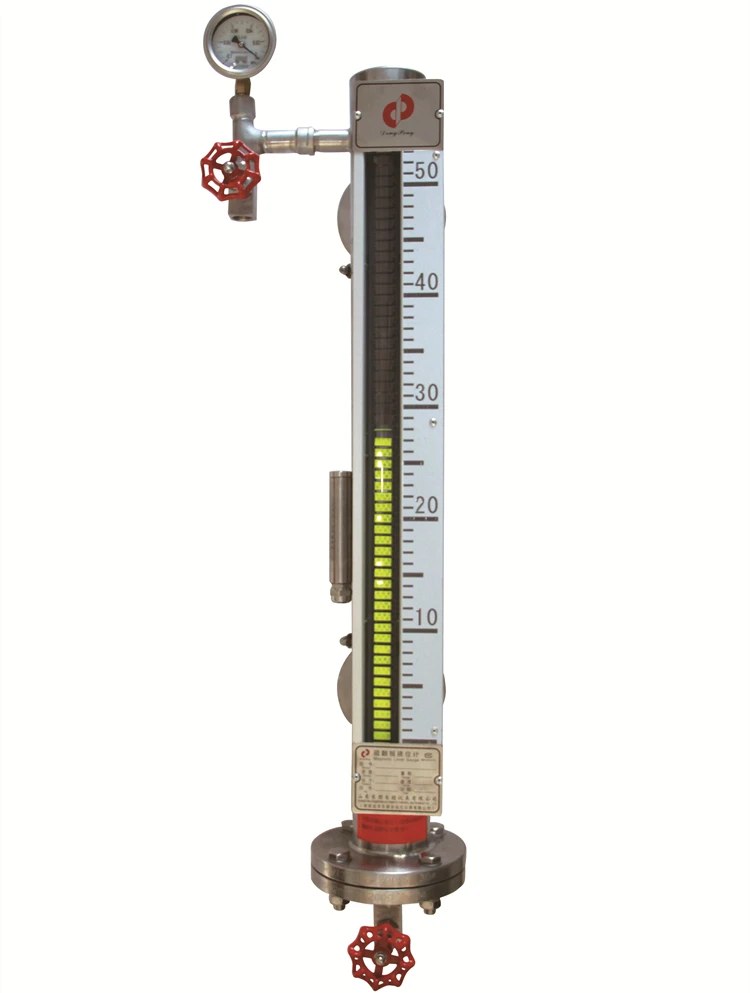

Az ultrahangos folyadék szint-érzékelők sok gyárban forradalmi változást hoztak, különösen akkor, amikor arról van szó, hogy mennyi víz van valójában a tárolóikban. A régi gyárak akkor használták ezt, amikor még nem volt érzékelőjük a mérésekhez, és csak mérőskálát vagy float kapcsolót használtak. A mérőskálák olvasása manuális feladat volt, ami időt vett, és néha hibás eredményekhez vezethetett. Ellenben a fényes új float kapcsolók biztosan tréfásak lehetnek és megbízhatatlanok, ha régebbi egység van.

A folyadék szint mérése korábban nehéz feladattá vált, most meg van ezekkel az érzékelőkkel, sokkal gyorsabb, könnyebb és pontosabb a folyadék szintje, ha már nem is működik. Ezek az érzékelők a szükséges elven működnek, így a gyárak bátran bízhatnak bennük a bármely folyadék szintjének pontos mérésére anélkül, hogy nagy problémák lennének.

A LiDAR-k viszont csak néhány alkalommal ellenőrizhetik a folyadék szintjét egy időszakos vizsgálat során, míg az ultrahangos érzékelők könnyebbek karbantartásban és csodálatosan energiahatékonyak, hiszen bárki szerint mindig is megtehetik azt, mivel működésük nem függ a fénytől. Ez lehetővé teszi nekik, hogy gyorsan észleljék a folyadék szintje közötti bármilyen változást, és figyelmeztethetik emberi műveletüket, ha valami elromlik. Ez a gyors reakcióidő lehetővé teszi a gyárak számára, hogy hatékonyabban működjenek, és minimalizálja a leállásokat, ami biztosítja a növekvő termelékenységet.

Számos tanúsítványt kaptunk Kínából. Másodszor, megkaptuk az robbanásvédelmi tanúsítványt, amelyet a kínai bányász-ipar elfogad (Ex d ia (ia Ga) q T6 Gb), továbbá megpróbáljuk megkapni az nemzetközi elismerést élő ATEX tanúsítványt. Emellett, a termelési munkateremünk is befejezte az összes tanúsítványt, valamint az ultrahangos folyadék-szint érzékelő-rendszerekért, a környezeti rendszerért, és megkaptuk a CE tanúsítványokat.

Teljes készletű, pontos mérőkalibrálási felszerelésünk van. Az általunk kapott China Institute of Metrology tanúsítvány is ezen kívül biztosítja, hogy minden általunk a gyárból szállított árammérő pontosan és igazán kalibrálva van. Rendelkezésre álló teljes nyomás- és víztightőség-tesztelési felszereléssel biztosítjuk, hogy a művelem, amelyet irányítok, képes és erős elég magasnyomású eszközök vagy IP68 biztonság előállítására. Rendszereztem egy szigorú és alapos minőségi ellenőrzési osztályt, és minden ellenőrzési lépés ultrahangos folyadék szintjének érzékelésével történik, hogy biztosak legyünk abban, hogy minden termék hibátlanul távozik a gyárból.

A cégnk már több éve együttműködik a helyi neves egyetemekkel, és sikerült felvennie és képeznie a legjobb technikai szakembereket. Ez nemcsak garantálja folyamatos technológiai fejlesztésünket és javításunkat, de folyamatosan javít és létrehoz új termékeket. Megoldást találhatunk azokra a különböző problémára és fájdalompontokra, amelyekkel az ügyfelek szembesülnek az ultrahangos folyadék szint-érzékelő projekteik során. Azonban a tehetség-stratégia segítségével professzionális technikai szakembereket is fejleszthetünk, konkrét kutatólaboratorikat biztosítva és együttműködve a cégben lévő haladó technológiai vállalatokkal az oktatás terén.

Prémium földrajzi helyen találhatók. 60 kilométeres sugaron belül van a Zhengzhou Nemzetközi Logisztikai Állomás, Kínai Közép-Kína legnagyobb légiforgalmi logisztikai állomása, bőséges logisztikai és légi lehetőségekkel; számos nemzetközi kifejező cég található itt, mint például FEDEX, UPS, DHL, TNT, stb. A Zhengzhou város 50 km-re van, és ez az ultrahangos folyadék szintjét érzékelő rögzítési hub Kínában. Összekapcsolja a Közép-Ázsia, Európa és Oroszország vasúti szállítási útvonalait. A szállítás velünk biztonságos és gyors, sokféle lehetőségből lehet választani.

Copyright © Kaifeng Kamboda Industrial Instrument Co.,Ltd All Rights Reserved - Adatvédelmi szabályzat