Un medidor de fluxo de líquido ultrasónico é un instrumento único que nos axuda a determinar a forma en que os líquidos pasan a través dos tubos. Non obstante, estes bebés son útiles porque miden a velocidade á que viaxa un líquido transmitindo ondas sonoras de alta frecuencia a través del. Aquí é onde imos explicar todas as vantaxes do uso dun medidor de fluxo de líquido ultrasónico, así como como funciona paso a paso e cales son as características que os diferencian que os fan controlables en diversas situacións.

Esta é outra gran cousa sobre os medidores de fluxo de líquido ultrasóns, que non precisan ser inseridos no tubo para que funcionen. Outros tipos de caudalímetros poden instalarse dentro da tubaxe, o que supón un reto e consume tempo. Por outra banda, os medidores de ultrasóns pódense instalar sen contacto para conectar a parte superior desta tubaxe. Isto axuda a instalalos ou utilizalos sen interromper o fluxo de líquido. Isto é fundamental porque en lugares como fábricas ou depuradoras, os líquidos deben seguir fluíndo e deter isto pode causar todo tipo de problemas. Ademais, dado que non se require ningunha modificación no tubo, ademais de eliminar os resonadores de tordos, a instalación prodúcese sen problemas e, polo tanto, aforra moito tempo aos zombies.

Poden medir unha ampla gama de líquidos, que é outro beneficio dos medidores de fluxo de líquido ultrasónicos. Estes poden traballar facilmente con auga, aceite e mesmo outros produtos químicos. Xa que poden usarse nunha variedade de industrias como a fabricación, a medicina e a limpeza de augas residuais. Estes medidores son axeitados en moitas aplicacións ao ter a capacidade de medir unha ampla gama de líquidos e, polo tanto, convérteos nunha ferramenta moi valiosa para calquera empresa.

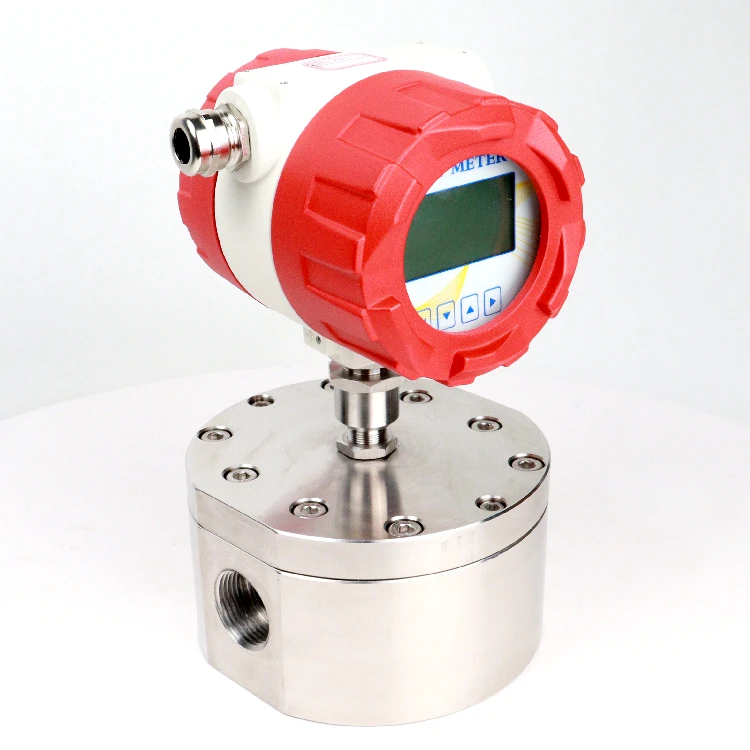

Como funcionan os medidores de fluxo de líquido ultrasónicos? Cando un líquido flúe, altera o seu movemento destas ondas sonoras. O medidor mide o tempo que tardan as ondas sonoras en regresar cara ao sensor. Unha vez que coñece a velocidade do son nese líquido en particular, o medidor pode calcular o caudal: canto fluído pasa por un tubo. As ondas sonoras son moi medidas de temperatura e presión, o que dá lugar a lecturas máis precisas dos medidores, mesmo en condicións de tubos irregulares.

Para un caudalímetro, a exactitude e a precisión son parámetros importantes. Os medidores de fluxo ultrasónicos (líquidos) son moi precisos e teñen unha alta precisión. Isto débese en parte a que non teñen pezas que se movan e se desgasten co paso do tempo, polo que son máis estables durante un período máis longo. A cuestión é que podes confiar nas súas medidas. Nun nivel básico, pódense axustar e programar para adaptarse ao líquido que se está a medir; pense nisto como marcando a liña entre "lecturas" e incluso lecturas do seguinte nivel que se aplican especificamente a outras variables.

En comparación con outros tipos de medidores de fluxo, os medidores de líquido ultrasónico son unha solución moi rendible para rastrexar a taxa de fluído que pasa por tubos individuais ou interconectados. Non necesitan modificacións particulares na tubaxe e, polo tanto, pódense configurar rapidamente cun tempo de inactividade mínimo. Isto é importante para que as empresas poidan manter unha siuática regular. Ademais, os medidores de fluxo ultrasónicos teñen unha maior esperanza de vida, o que implica que son capaces de funcionar de forma consistente; a precisión e coherencia na súa lectura nunca se ve afectada durante un longo período. O aforro nos fluxos pode sumar e axudar a manter as organizacións en marcha co mínimo gasto.

A nosa empresa leva moito tempo colaborando con universidades nacionais coñecidas, atraendo e adestrando o talento tecnolóxico de punta, o que non só garante que esteamos sempre avanzando na nosa innovación tecnolóxica, ademais de mellorar continuamente e engadir novos produtos. Somos capaces de atopar solucións a diferentes problemas e puntos de dor aos que se enfrontan os clientes en varios proxectos. O plan de talento que desenvolvemos tamén axuda a desenvolver profesionais con medidor de fluxo de líquido ultrasónico técnico a través de laboratorios de investigación específicos e colaborando na industria con empresas de tecnoloxía avanzada que se desenvolven.

Temos un conxunto completo de equipos de calibración de medición precisa e somos certificados polo Instituto de Metroloxía de China, asegurándonos de que cada medidor de fluxo que enviamos fóra da fábrica foi calibrado cun fluxo real é preciso e verdadeira precisión. Tamén teño o equipo completo de proba de presión e impermeable. Isto é para asegurarme de que as miñas instalacións sexan o suficientemente fortes e sexan capaces de fabricar instrumentos de alta presión a medida de seguridade IP68. O noso departamento de control de calidade é completo e estrito. Cada paso está coidadosamente planificado para asegurarse de que o produto é un medidor de fluxo de líquido ultrasónico despois de que saia da fábrica.

Estamos situados nunha localización xeográfica premium. Dentro de 60 quilómetros, hai Zhengzhou International Logistics Port, o maior porto loxístico aéreo da China Central, con abundantes opcións loxísticas e aéreas; Hai moitas empresas internacionais de medidores de fluxo de líquidos por ultrasóns, como FEDEX, UPS, DHL, TNT, etc. Zhengzhou City está a 50 km de distancia, é o maior centro ferroviario de China. Ten rutas directas de transporte ferroviario que conectan con Asia Central, Europa e Rusia. Así, o envío de nós é rápido e seguro e hai moitas rutas para escoller.

Primeiro obtivemos varios certificados de aprobación de formularios en China e, en segundo lugar, obtivemos un certificado a proba de explosión que é un medidor de fluxo de líquido ultrasónico da industria mineira de carbón (Ex d ia(ia Ga) q IIC T6 Gb), e estamos a buscar o certificación internacional ATEX a proba de explosión; Ademais, o noso taller de produción pasou un conxunto completo de certificacións ambientais e do sistema de calidade e obtivo certificados; finalmente, tamén teñen certificacións CE; certificación de calidade ISO completa, etc.

Copyright © Kaifeng Kamboda Industrial Instrument Co., Ltd Todos os dereitos reservados - Política de Privacidade